Why a stretch wrapping machine is a strategic investment for logistics

Why a stretch wrapping machine is a strategic investment for logistics

Blog Article

Enhance Your Product Packaging Process With a Trusted stretch wrapping machine for Optimal Efficiency

In the intricate globe of logistics, an efficient product packaging process is an essential factor that can considerably impact a firm's bottom line. The unification of a trusted stretch wrapping machine not just maximizes efficiency but additionally makes certain the stability of goods during transportation - stretch wrapping machine.

Comprehending the Role of a stretch wrapping machine in Packaging

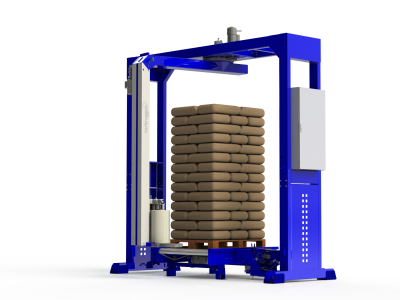

Ensuring product security during transit, a stretch wrapping machine stands as a pivotal property in the packaging industry. Its primary function focuses on enveloping things in a protective layer of movie, thus maintaining item stability and minimizing damages risks throughout transportation.

The equipment's operation is elaborate yet efficient. Goods are put on a turning base while the film is untangled from a fixed roll. As the turntable rotates, the film is applied consistently over the items, making sure complete coverage.

This machine's significance extends beyond plain covering. stretch wrapping machine. It boosts the piling stability of products, decreasing the chance of mishaps. Further, it safeguards items from dirt, dampness, and other ecological elements, keeping their top quality till they get to the consumer

Essentially, a stretch wrapping machine is a vital tool for services seeking to maximize their packaging process, secure their items, and simplify their logistics procedures. Its role is essential to the efficient and effective performance of the modern-day product packaging market.

Trick Features to Take Into Consideration When Choosing a stretch wrapping machine

When picking a stretch wrapping machine for packaging purposes, numerous essential functions call for consideration. These consist of evaluating the maker's performance, understanding its lots capacity, and examining its resilience and maintenance requirements. An educated decision depend upon a complete evaluation of these factors.

Although performance could not be the very first thing you believe of when thinking about stretch wrapping makers, it is an essential variable that can dramatically influence your product packaging process. A faster equipment can cover much more bundles in less time, improving your operation's result. The maker's energy intake is another important factor, as a machine that uses much less power can cut operating costs.

The Influence of a Trusted stretch wrapping machine on Performance Degrees

Purchasing a reliable stretch wrapping machine can significantly enhance efficiency degrees in a product packaging procedure. These equipments automate the wrapping procedure, allowing for effective and regular efficiency that outpaces hand-operated covering methods.

A dependable machine reduces downtime created by mechanical failures or upkeep requirements. This makes certain a consistent circulation of job, stopping delays and backlog in the production chain. High-grade stretch wrapping equipments also have adjustable settings for various product types. This adaptability allows businesses to deal with a wide series of items without lengthy manual adjustments.

Moreover, these devices need much less human treatment, freeing up workers to concentrate on other essential tasks. This optimisation of personnels can cause a boost in overall operational performance.

Basically, a reputable stretch wrapping machine is a valuable investment that can improve productivity levels in a packaging operation, giving significant advantages in resource, adaptability, and performance utilisation.

Ways in Which a stretch wrapping machine Reduces Waste

A stretch wrapping machine's function in waste reduction is considerable and complex (stretch wrapping machine). Not just does it minimize product usage by efficiently wrapping items, however it also safeguards products from damages throughout handling and transportation. This double benefit outcomes in remarkable expense financial savings and advertises sustainability in the packaging process

Minimizing Product Use

Cost and Time Cost Savings: The Economic Benefits of a stretch wrapping machine

Additionally, the maker's regular wrapping technique minimizes item damage, lowering substitute prices and enhancing customer fulfillment. Making use of a stretch wrapping machine additionally brings about an extra predictable budgeting process, as the quantity of stretch film used per pallet is regular, unlike hands-on covering which can differ greatly.

Inevitably, the collective cost savings in labor, products, and possible product loss make the first financial investment worthwhile. In the lengthy term, companies can attain considerable financial benefits by incorporating a stretch wrapping machine into their product packaging procedure.

Conclusion

Although efficiency may not be the first thing you assume of when taking into consideration stretch wrapping devices, it is an essential element that can substantially impact your packaging procedure. The maker's power intake is another crucial factor, as a maker that uses much less energy can reduce running costs. Furthermore, a device sustained by an extensive guarantee and superb client solution can minimize potential problems in preserving the machine's optimal performance.To understand the ways in which a stretch wrapping machine minimizes waste, one must initially think about the innovative layout of these machines. In this means, stretch wrapping equipments not only improve the high quality of packaging but likewise promote an extra environmentally-friendly and efficient process, showing their important duty in contemporary product packaging operations.

Report this page